What is a slip ring?

Figure 1: Jib crane with a rotating upper arm and fixed base.

A slip ring is a method to make an electrical connection from a stationary object to a rotating assembly. These are used in many industrial automation applications and for equipment like tower and jib cranes, as well as cable and hose winders, where a portion can spin freely, while the base is fixed. Windmills also use slip rings to conduct electricity between the upper spinning portion to the fixed base. There are many names used for this, type of device. I’ve found the terms power slip rings, electric swivel, or collector rings with just a quick search. a method to make an electrical connection from a stationary object to a rotating assembly.

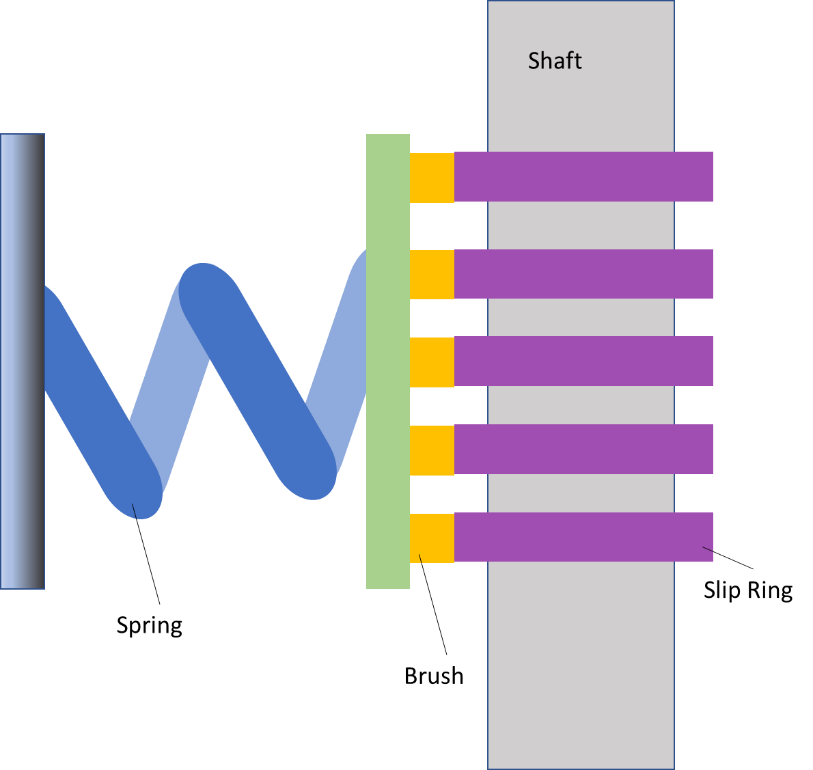

The Basics: How Slip Rings Work

The basic concept is to use springs to press a series of brushes against a rotating ring. Depending on the design and rpm requirements, the brushes can be fixed with a rotating ring, or the ring can be fixed with the brushes rotating. In either arrangement, the series of brushes maintain contact with the ring via the pressure from the springs. Electricity is conducted from the fixed component to the rotating component via the shaft and ring making contact.

Figure 2: Carnival Rides use slip ring collectors.

The slip rings Springer Controls offers, manufactured by Tecno Elettrica Ravasi (TER) are made of brass. Depending on the current requirements, the brushes can be made of graphite or phosphor bronze. Phosphor bronze offers better conductivity and wear life, but graphite is more economical.

Wireless slip rings offer some benefits to the brushed slip ring because they don’t have the brush/slip ring contact point which can wear over time. A wireless slip ring uses a magnetic field to transfer power and data over a small air gap between the rotating and fixed portions of the slip ring. Wireless slip rings are limited in terms of how much power can be transmitted and thus are not suitable for all applications.

Finding the Right Slip Ring Collector For Your Application

Figure 3: Basic Side view cross-section diagram of a Slip Ring Collector.

Springer Controls offers many variations on this same brushed slip ring concept depending on the application requirements. For small requirements, we offer the 10A slip ring collector, which has a compact size, with 4 rings each rated for up to 10A current at 400VAC. We also offer a 10A/30A slip ring collector which can be configured in a variety of ways with both 10A and 30A rated rings. For even higher current, we offer a 50A slip ring collector with up to 16 rings each rated for 50A. Finally, TER has introduced the 300A/500A slip ring collector, capable of transmitting DC power, and handling data transmission at speeds up to 100Mbit/s using Ethernet, ProfiBus, ProfiNet, LAN, CAN-Bus and CANOpen protocols in addition to transmitting up to 500A of AC power.

If you would like to learn more about this product or other devices that Springer Controls sells, please contact one of our experts. We would be happy to help!